Have you ever wondered what makes a vacuum cleaner suck up dirt so effectively? It all comes down to something called negative pressure.

Understanding negative pressure in a vacuum is key to unlocking how many everyday devices work, from household cleaners to advanced scientific tools. If you want to know what negative pressure really means and why it matters for your daily life or work, keep reading.

This simple concept can change the way you see the power behind vacuums and much more.

Negative Pressure Basics

Negative pressure means the air pressure is lower than normal. It happens when air is removed from a space. This creates a vacuum effect, pulling air or fluid inside.

Positive pressure is the opposite. It means the air pressure is higher than normal. It pushes air or fluid out of a space.

Think of a syringe. Pulling the plunger creates negative pressure, drawing liquid in. Pushing the plunger creates positive pressure, forcing liquid out.

| Type of Pressure | Pressure Level | Effect |

|---|---|---|

| Negative Pressure | Lower than normal | Pulls air or fluid inside |

| Positive Pressure | Higher than normal | Pushes air or fluid out |

Credit: blog.ashcroft.com

How Negative Pressure Occurs

Negative pressure happens when air or gas is taken out of a space. This creates a space with less pressure than the air outside. The process starts by removing air from an area, often using a pump or vacuum device. This makes the pressure inside lower than the outside air pressure.

Common ways to create negative pressure include:

| Method | Description |

|---|---|

| Mechanical Pumps | These remove air by physically moving it out of a space. |

| Venturi Effect | Uses fast-moving fluids to pull air out and lower pressure. |

| Steam Ejectors | Steam flow creates suction, pulling air from the area. |

| Vacuum Chambers | Enclosed spaces where air is pumped out to reduce pressure. |

Applications Of Negative Pressure

Negative pressure finds many uses across different fields. In industry, it helps move liquids and gases safely. Factories use it to keep harmful dust and fumes away from workers. It also helps in packaging to keep food fresh by removing air.

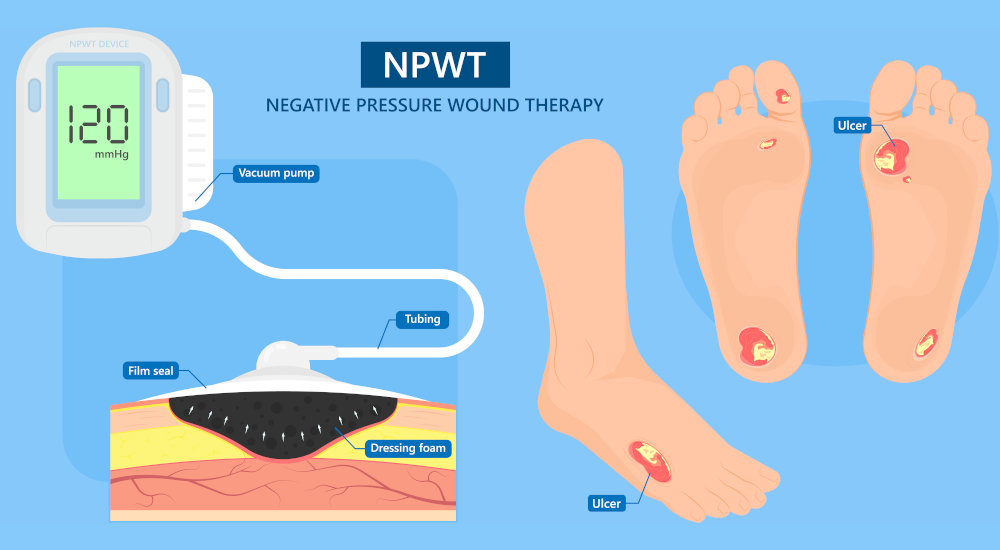

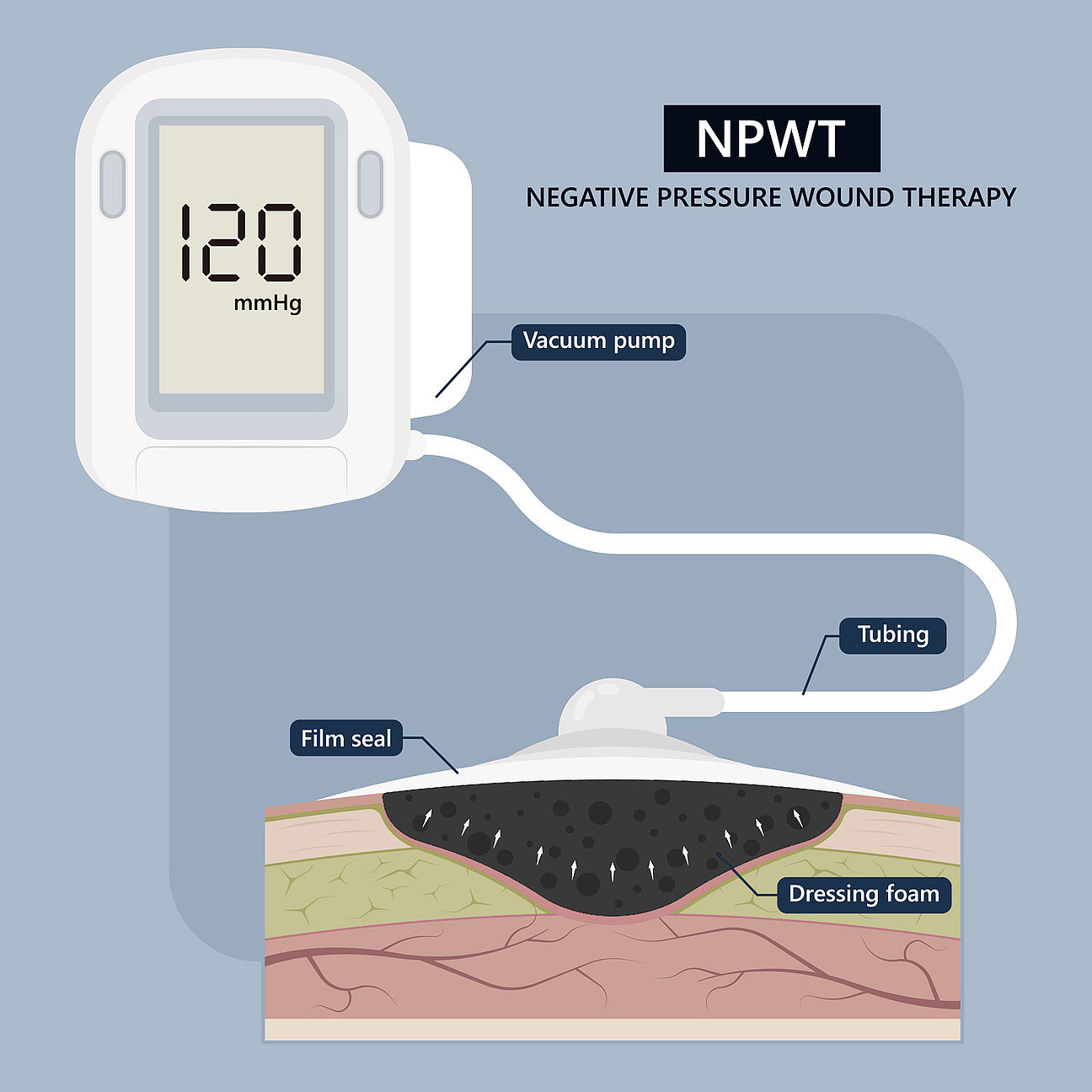

In the medical field, negative pressure aids wound healing. Special machines create a vacuum to draw out fluids and germs. Hospitals use it to control infections by stopping bad air from spreading.

Scientific research uses negative pressure to study air and liquids. It helps create clean rooms where tiny dust particles are removed. Scientists use it in experiments that need precise control of air or gases.

Measuring Negative Pressure

Negative pressure is measured using special instruments that show how much pressure is below normal. These tools help check vacuum systems and make sure they work right. Common tools include manometers, vacuum gauges, and pressure transducers. Manometers use liquid levels to show pressure. Vacuum gauges often have needles that move to show pressure changes. Pressure transducers change pressure into electric signals for easy reading.

Different units measure negative pressure. The most used units are Pascal (Pa), millimeters of mercury (mmHg), and inches of mercury (inHg). Sometimes, atmospheres (atm) or bar are used. These units tell how much less pressure there is than normal air pressure. Understanding these numbers helps control machines and keep safety.

Benefits And Challenges

Negative pressure in vacuum helps move fluids and gases easily. It is used in many industries like healthcare, manufacturing, and food packaging. Hospitals use it to keep rooms clean and stop germs from spreading. Factories use it to hold parts tightly during assembly. Food packaging stays fresh longer with vacuum sealing.

Negative pressure also saves energy by reducing air leaks. Machines work better with less dust and dirt inside. This improves product quality and safety. It makes processes faster and more reliable.

Some risks include equipment failure and leaks. If the vacuum breaks, it can cause damage or contamination. Also, maintaining negative pressure needs regular checks and repairs. Sometimes, it needs special training for workers to use it safely.

| Advantages | Challenges |

|---|---|

| Improves cleanliness | Needs regular maintenance |

| Keeps products fresh | Risk of leaks or failure |

| Reduces energy use | Requires skilled operators |

| Enhances safety | Costs for equipment upkeep |

Credit: certifiedfoot.com

Negative Pressure Safety Tips

Always wear protective gloves and goggles during handling. Avoid touching vacuum parts with bare hands. Use tools designed for vacuum systems to reduce risk. Make sure the area is well-ventilated to prevent gas buildup. Check all connections for tightness before starting work.

Regular maintenance is key. Clean filters and seals often to keep the system running well. Look for any signs of wear or damage. Use a pressure gauge to monitor vacuum levels continuously. Report any unusual readings or noises immediately.

Credit: www.schwarzer.com

Frequently Asked Questions

What Is Negative Pressure In Vacuum Systems?

Negative pressure in vacuum systems means pressure below atmospheric level. It creates a partial vacuum by reducing air pressure inside a space. This helps in suction, containment, and controlling air flow in various applications.

How Does Negative Pressure Differ From Positive Pressure?

Negative pressure is lower than atmospheric pressure, while positive pressure is higher. Negative pressure pulls air inward, and positive pressure pushes air outward. Both control airflow but serve different purposes in ventilation and vacuum systems.

Why Is Negative Pressure Important In Vacuum Technology?

Negative pressure enables vacuum creation, essential for suction, material handling, and sealing processes. It improves system efficiency and performance by maintaining controlled low-pressure environments.

What Are Common Uses Of Negative Pressure In Industry?

Industries use negative pressure for vacuum packaging, medical suction, HVAC systems, and contamination control. It helps maintain clean environments and efficient material movement.

Conclusion

Negative pressure in a vacuum means lower pressure than the air outside. It helps in many tools and machines to work well. This concept is simple but important in science and industry. Understanding it can improve how we use vacuum systems every day.

Keep in mind, negative pressure is about creating space with less air. It makes suction and movement possible. Knowing this helps you see how many devices function. Negative pressure plays a quiet but vital role in technology and nature.