Have you ever wondered how factories keep the air clean and safe while working with dust and tiny particles? Dust separation technology is the secret behind this.

It’s a powerful way to remove harmful dust from the air, protecting your health and the environment. You’ll discover what dust separation technology is, how it works, and why it matters to you. Understanding this can help you see how industries stay safe and why clean air is so important for your well-being.

Keep reading to unlock the simple science behind dust separation and how it impacts your daily life.

Basics Of Dust Separation

Dust particles vary in size and type. They can be solid or liquid. Common types include fine dust, coarse dust, and fibers. Fine dust is tiny and hard to see, while coarse dust is larger and settles quickly.

Dust comes from many sources. Construction sites, factories, and farms produce lots of dust. Even roads and homes add dust through dirt and debris. Dust affects air quality and health.

Removing dust is important for safety and cleanliness. It helps protect lungs and prevents equipment damage. Dust separation technology cleans air by trapping dust particles, making the environment healthier and safer.

Common Dust Separation Methods

Mechanical separation uses physical barriers or gravity to remove dust. Screens and filters catch dust particles. Gravity helps heavier dust fall out of the air.

Electrostatic precipitation charges dust particles using electricity. The charged particles stick to plates inside the machine. This method cleans air without using filters.

Cyclone separators spin air fast in a round chamber. Centrifugal force pushes dust to the outside walls. Dust falls into a container below, leaving cleaner air.

Baghouse filters use fabric bags to trap dust. Air passes through the bags, but dust stays inside. Bags are shaken or cleaned to remove dust buildup.

Advanced Technologies In Dust Separation

Wet scrubbers use water or liquid to trap dust particles from the air. They are good for removing large dust and gases. The dust sticks to the liquid and falls into a collector.

Pulse jet filters clean dust by shaking it off filter bags using a strong burst of air. This keeps the filters clear and working well. They are good for fine dust and have low maintenance.

Nanofiber filters use very thin fibers to catch tiny dust particles. They are very effective at cleaning air and can trap particles smaller than a micron.

Hybrid systems combine two or more dust removal methods. This helps to clean different types and sizes of dust more efficiently. They are used where dust is very mixed or hard to remove.

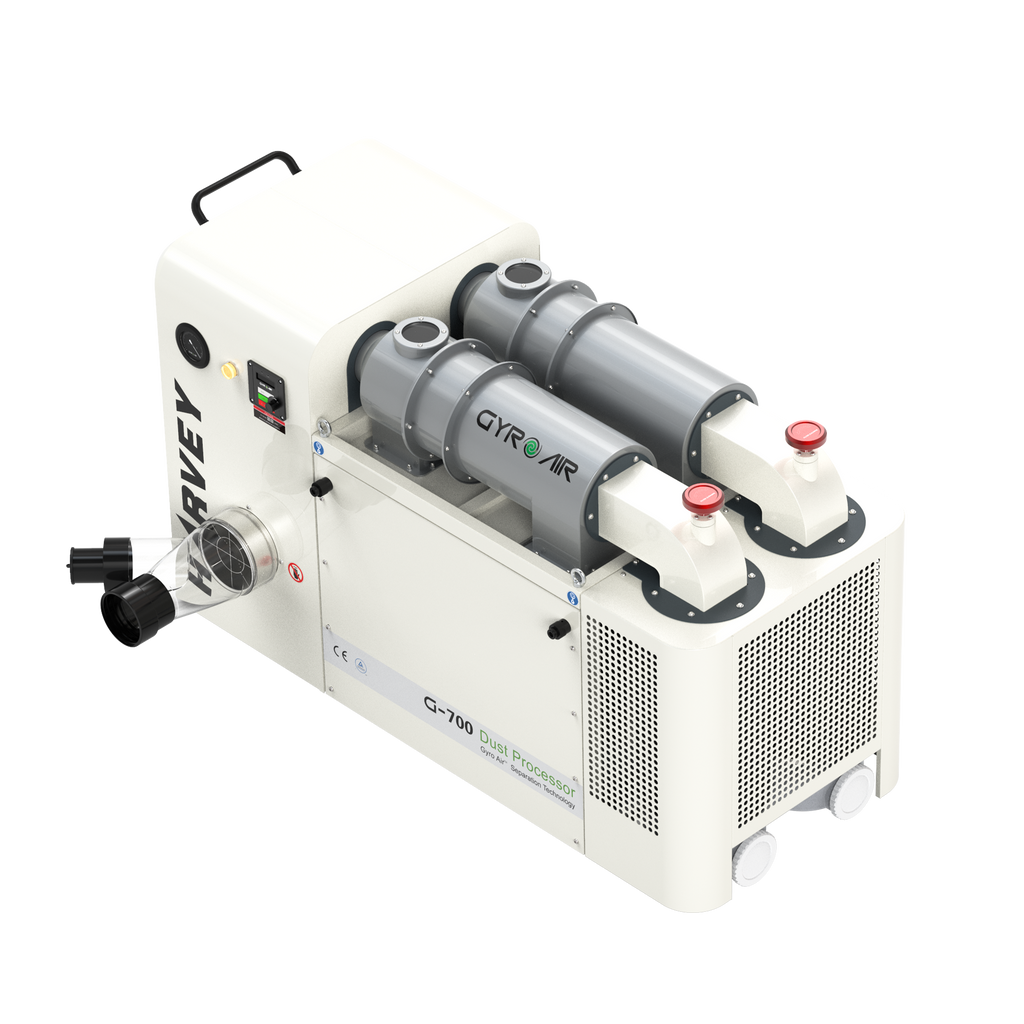

Credit: www.harveywoodworking.com

Applications Across Industries

Dust separation technology helps keep air clean in many industries. In manufacturing and processing, it removes dust from the air to protect machines and workers. This stops machines from breaking and keeps workers healthy.

In pharmaceutical production, dust separation is very important. It stops tiny particles from mixing with medicines. This keeps the medicines pure and safe to use.

The mining and quarrying industry uses dust separators to reduce dust clouds. This helps miners breathe easier and lowers the risk of accidents. It also keeps the environment cleaner.

In the food and beverage industry, dust separation keeps food clean. It stops dust from landing on food during processing. This helps keep food fresh and safe to eat.

Benefits Of Efficient Dust Separation

Efficient dust separation helps keep the air clean. It removes tiny dust particles from the air, making it safer to breathe. This improves air quality inside buildings and factories.

Better air means fewer health problems. Workers and residents feel healthier and safer. Dust can cause coughs, allergies, and breathing issues. Removing dust lowers these risks.

Many places have rules about dust. Using dust separation makes it easier to follow these rules. It helps businesses avoid fines and legal trouble.

Operations run smoother without dust buildup. Machines last longer and need less fixing. Dust-free areas are cleaner and safer for workers. This saves money and time.

Credit: www.harveywoodworking.com

Challenges And Solutions

Fine particles are hard to catch. They can slip through filters easily. This makes dust separation tricky. Special filters and tech help trap these tiny bits. Regular cleaning keeps systems working well.

Energy use is a big concern. Dust systems need power to work. Using energy-saving machines lowers bills. Smart designs reduce how much power is needed.

Parts wear out over time. Machines need easy maintenance to stay strong. Durable materials last longer and cut repair costs. Regular checks help spot problems early.

| Cost Factor | Details |

|---|---|

| Initial Setup | Can be high due to advanced filters and equipment |

| Running Costs | Energy and maintenance add to expenses |

| Long-term Savings | Good systems reduce health risks and clean air costs |

Future Trends In Dust Separation

Smart monitoring systems help track dust levels in real time. They send alerts when filters need cleaning or replacing. This keeps machines working well and saves energy.

Sustainable technologies focus on reducing waste and energy use. New dust separators use less power and last longer. Some systems recycle dust for other uses, cutting pollution.

Integration with IoT means dust separators connect to the internet. This allows remote control and better data analysis. Factories can fix problems faster and improve air quality.

Innovations in filter materials bring stronger, lighter filters. These filters catch smaller dust particles. They also last longer and need less cleaning. This helps keep the air cleaner and machines safer.

Credit: www.ebay.com

Frequently Asked Questions

What Is Dust Separation Technology Used For?

Dust separation technology is used to remove dust particles from air or gas streams. It improves air quality and protects equipment. Commonly applied in industries like manufacturing, mining, and HVAC systems to ensure cleaner environments and comply with environmental regulations.

How Does Dust Separation Technology Work?

Dust separation technology works by capturing dust particles using filters, cyclones, or electrostatic precipitators. It separates dust from the air using physical or electrical forces. Clean air is then released, while dust is collected for disposal or recycling.

What Are Common Types Of Dust Separation Methods?

Common dust separation methods include cyclonic separation, baghouse filters, electrostatic precipitators, and scrubbers. Each method targets different particle sizes and types. The choice depends on industry needs, dust characteristics, and environmental standards.

Why Is Dust Separation Technology Important For Industries?

Dust separation technology prevents pollution, protects worker health, and reduces equipment wear. It helps industries comply with safety and environmental laws. Efficient dust control also improves operational efficiency and product quality.

Conclusion

Dust separation technology helps keep air clean and safe. It removes dust and particles from the air easily. This technology protects machines and workers from harm. It also improves air quality in homes and factories. Many industries use dust separators every day.

Choosing the right system depends on the type of dust and space. Understanding this technology helps make better choices for health. Clean air means a better place to live and work. Dust separation is simple but very important.