Have you ever wondered how vacuum cleaners manage to suck up dirt so effectively? The secret lies in how vacuum airflow is controlled.

Understanding this simple yet powerful process can help you choose the right vacuum or even improve your current one’s performance. You’ll discover the key factors that control airflow, why they matter, and how they affect your cleaning results. Keep reading, and you’ll gain insights that can make your next cleaning session easier and more efficient.

Basics Of Vacuum Airflow

Vacuum airflow means moving air using low pressure. It happens when air is pulled from one place to another. This flow helps machines work well and keeps spaces clean.

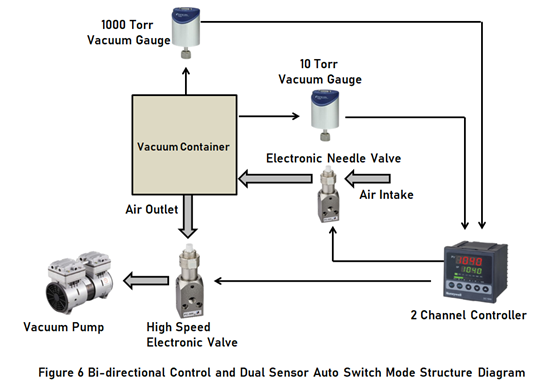

Some key parts help control vacuum airflow. A vacuum pump creates the low pressure that moves air. Valves open and close to guide air paths. Filters stop dust and dirt from entering the system. Tubes and pipes carry air to different spots.

These parts work together to keep air moving smoothly. Controlling airflow means adjusting how much air moves and where it goes. This control is important for safety and efficiency.

Credit: www.amazon.com

Methods To Control Vacuum Airflow

Mechanical control techniques use moving parts to change airflow. Devices like fans, dampers, and pistons adjust the vacuum’s strength. These tools are simple and reliable. They often need manual setting or basic automation.

Electronic control systems use sensors and computers to manage airflow. They can monitor pressure and adjust vacuum power automatically. These systems offer precise control and save energy by running only when needed.

| Method | Description | Advantages |

|---|---|---|

| Mechanical Control | Uses physical parts like valves and dampers | Simple, reliable, easy to maintain |

| Electronic Systems | Uses sensors and computer controls | Precise, energy-efficient, automatic |

| Valves and Regulators | Directly control airflow by opening or closing | Fast response, adjustable flow rates |

Valves and regulators control vacuum flow by opening or closing paths. They provide quick changes in airflow and keep pressure steady. These parts are key for safe and smooth operation.

Factors Affecting Airflow Control

Pressure variations directly impact vacuum airflow. Lower pressure increases airflow speed, while higher pressure slows it down. Small changes can cause big effects in the system.

Temperature influence affects air density. Warm air is less dense and flows faster. Cold air is denser and moves slower. This changes how the vacuum system works.

System design considerations include pipe size, shape, and length. Smooth pipes reduce resistance and help airflow. Sharp bends and narrow pipes cause pressure drops and slow the flow.

Common Challenges In Airflow Control

Leakage issues cause loss of vacuum pressure. Small cracks or gaps let air escape. This reduces the system’s efficiency and can stop it from working properly. Seals and joints need regular checks to avoid leaks.

Flow instability happens when air moves unevenly through the system. This can cause changes in pressure and reduce suction power. It makes controlling airflow difficult and can affect the machine’s performance.

Maintenance and wear are common problems. Parts like filters and valves wear out over time. Dirt buildup also blocks airflow. Regular cleaning and part replacement keep the system running smoothly.

Advanced Techniques In Vacuum Airflow Management

Automated control systems adjust vacuum airflow quickly and precisely. Sensors detect changes in pressure and flow. Then, controllers send signals to valves or pumps. This keeps the airflow stable and efficient.

Real-time monitoring tools show airflow data on screens instantly. Operators can see if airflow drops or rises. Alerts help fix problems before they grow. This saves time and prevents damage.

Integration with IoT connects vacuum systems to the internet. Data is shared with smartphones or computers. This allows remote control and easy tracking. Smart devices help improve system performance and reduce costs.

Credit: www.cleva-uk.com

Applications Of Controlled Vacuum Airflow

Controlled vacuum airflow is vital in many fields. In industrial manufacturing, it helps move parts and control machines precisely. It keeps processes smooth and efficient. In medical equipment, vacuum airflow powers devices like suction machines. It ensures safety and accuracy in treatments. In research and development, controlling airflow helps in experiments. It creates the right conditions for testing and measuring. Each area needs exact airflow control to work well and avoid errors.

Credit: www.genndih.com

Frequently Asked Questions

How Is Vacuum Airflow Measured Accurately?

Vacuum airflow is measured using devices like mass airflow sensors or manometers. These tools ensure precise readings by detecting pressure differences and flow rates. Accurate measurement helps maintain system efficiency and proper vacuum levels in various applications.

What Components Control Vacuum Airflow In Systems?

Vacuum airflow is controlled by valves, regulators, and sensors. Valves adjust airflow volume, regulators maintain pressure, and sensors monitor changes. Together, they ensure stable and efficient vacuum system operation.

Why Is Controlling Vacuum Airflow Important?

Controlling vacuum airflow prevents system damage and maintains optimal performance. Proper control ensures consistent pressure, energy efficiency, and prevents contamination or leaks in industrial and scientific applications.

How Do Vacuum Valves Regulate Airflow?

Vacuum valves regulate airflow by opening or closing passages. They adjust flow rate based on system demand, maintaining desired vacuum levels and preventing pressure fluctuations. This ensures smooth and reliable system operation.

Conclusion

Controlling vacuum airflow ensures machines work well and last longer. Simple tools like valves and regulators adjust the air flow easily. These controls keep pressure steady and avoid damage. Knowing how airflow works helps you fix problems fast. Clean filters and regular checks improve vacuum performance.

Small changes make a big difference in efficiency. Keeping airflow balanced supports smooth operation every time. Understanding these basics helps anyone manage vacuum systems better.